At FaktorPlus, we treasure our customers of long-standing and the numerous projects, we have achieved together. However, since these projects are often linked to innovations, we cannot talk openly about all success stories, but we still like to present some anonymized examples. A good solution must be »made for the customer«, and it must be an optimal fit for them. Thus we approach our projects from a neutral stance, with the necessary distance and matching foresight.

The customer already had a more reliable, but older workshop software for the use of which the operating procedures were coordinated and worked well. A disadvantage of the existing solution was, on the one hand, the countless paper printouts and, on the other hand, the time-consuming, manual and time-shifted feedback of the orders.

FaktorPlus developed a bidirectional interface between the workshop software and the FP MONITORING system to digitally synchronize the order parameters between the two systems. Newly created applications clearly display all relevant order data. This means that the foremen can now delegate and prioritize assignments directly in the system. In the third step, tablet applications were created, which are now used by the technicians to view orders, process them according to the instructions and then report their feedback digitally. By using our telematics hardware in the vehicles, the system can show the installer the exact parking position of the buses in the large depot, thus saving a considerable amount of time. All service measures are logged by the FP MONITORING system and are available to workshop employees in the form of a »digital service booklet«. After an extensive test, the system went into regular operation in January 2022.

CUSTOMER: Local public transport service

INDUSTRY: Passenger transport

SEGMENT: Digitization, software development, interface development

FaktorPlus has already advised the customer on the application for funding and supported them right until focused consulting ended. After analyzing the climate protection measures already taken and defining the status quo, a customer-specific strategy was developed and the focus of action identified. As part of the presentation of the results, FaktorPlus also provided information about useful additional steps and potential funding opportunities in the field of climate protection.

CUSTOMER: Local waste disposal company

INDUSTRY: Disposal

SEGMENT: Planning, consulting

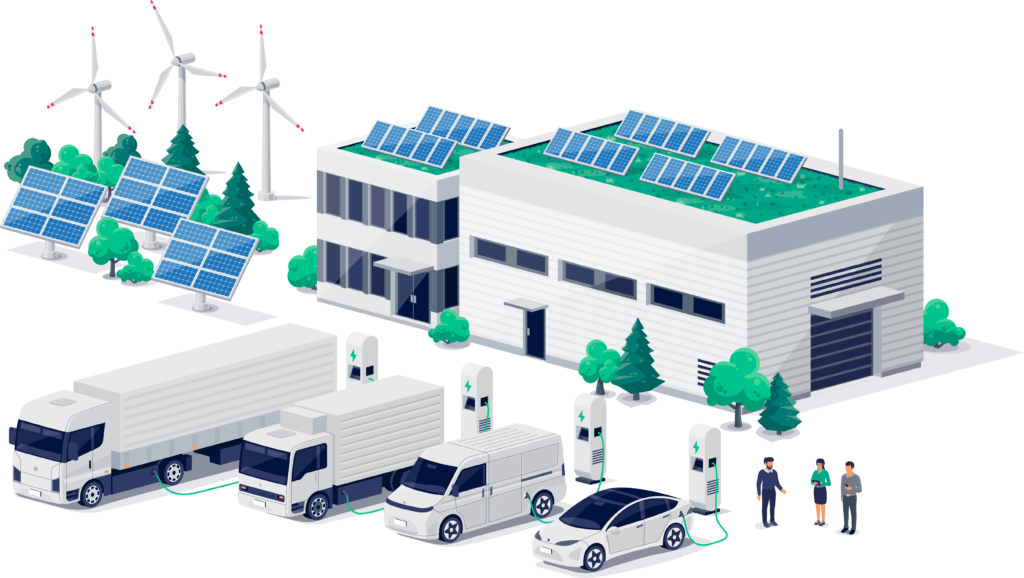

A feasibility study was carried out for a customer from the waste management industry with a view to switching to alternative, more environmentally-friendly drive technologies. A market analysis showed that there are two practically relevant vehicle technologies in the waste disposal segment: vehicles powered by hydrogen and electric vehicles Consideration was also given to the fact that the charging infrastructure is currently not yet available as well as to potentials for generating hydrogen or electricity (photovoltaics) on site. As part of the presentation of the results, FaktorPlus also provided information about useful additional steps and potential funding opportunities in the field of climate protection.

CUSTOMER: Local waste disposal company

INDUSTRY: Disposal

SEGMENT: Planning, consulting

Analysis of hydrogen generation potential in a landfill

The customer considered the installation of a hydrogen electrolysis plant for the production of green hydrogen on the site of an existing landfill and, if necessary, to use it to operate fuel cell vehicles. For this purpose, a fundamental analysis of the technically feasible renewable power generation potential (PV) was carried out. Finally, vehicle manufacturer data was used to estimate how many fuel-cell driven commercial vehicles could be operated with this technology.

CUSTOMER: Local waste disposal company

INDUSTRY: Disposal

SEGMENT: Planning, consulting

Hydrogen injection in diesel engines (»dual fuel«)

At the customer's site, the MultiGas Injection System (MGI system) was installed on both a generator and its vehicles. This allowed the partial admixture of hydrogen to conventional diesel fuel. By substituting part of the diesel, the customer is both able to achieve savings in fuel costs and to significantly improve the environmentally friendly emission behavior of the engine. Based on elaborate measurements, we were actually able to finally demonstrate the savings achieved.

CUSTOMER: Industry

INDUSTRY: Construction company, open-pit mining

TERMS OF REFERENCE: Hydrogen injection in diesel engines (»dual fuel«)

Our customer already used leading industry software to manage their garbage tours and was now looking for a solution to visualize this process via tablet in the disposal vehicle on a daily basis to ensure that even drivers without local knowledge approach all garbage bins, without forgetting anyone.

In the first step, an interface was defined that provides all the necessary information from the industry software. FaktorPlus then developed both a desktop app for visualizing the tours and modifying the predefined drivers and vehicles as well as a tablet version for displaying the tour in the garbage truck. This makes it easy for the driver to see whether he has already covered all the roads belonging to the respective tour and which ones may still be missing. At the end, the app shows a summary for final confirmation by the driver. The application has been successfully used by customers since 2018.

CUSTOMER: Local waste disposal company

INDUSTRY: Disposal

SEGMENT: Software development, interface programming (interface)

The customer was looking for a way to reduce their enormous fuel costs and, at the same time, improve the ecological balance and improve the operational readiness of their vehicles and machines. In 2005, the customer became aware of our patented FaktorPlus CO2 system. The three components FP PURGE, FP ENERGIZE and FP 4000 were optimally suited for this intended use and are still being used today. Over time, the need arose to document consumption and working hours more accurately and to be able to subsequently analyze them. This led to the use of the FP MONITORING system and thus, among other things, to the accurate monitoring of tank fill levels, GPS positions, digitization of master data and maintenance intervals as well as inventory management of objects even without permanent power supply. In addition, we were able to integrate individual software solutions for the customer, which were specifically tailored to their needs.

CUSTOMER : Drilling industry

INDUSTRY: Drilling, vehicles, machines, tanks, generators, assets

SEGMENT: Product application FaktorPlus CO2 system

(FP PURGE, FP ENERGIZE, FP 4000), FP MONITORING, Software development

The customer was looking for ways to reduce fuel costs and reduce harmful emissions from their vehicle fleet in parallel. With the FP PURGE, FP ENERGIZE and FP 4000 components, we have the optimal solution in our portfolio. The subsequent integration of the FP MONITORING system was carried out in the first step on the vehicle fleet and in the second on the tank system. This step enabled the customer, among other things, to accurately analyze fuel consumption with subsequent route optimization and to automatically notify the customer's own petrol station in the event of a low fuel level. Our products receive public funding as part of the de minimis funding program.

CUSTOMER: Timber trade

INDUSTRY: Transport, vehicles, tanks

SEGMENT: Product application – FaktorPlus CO2 system

(FP PURGE, FP ENERGIZE, FP 4000), FP MONITORING